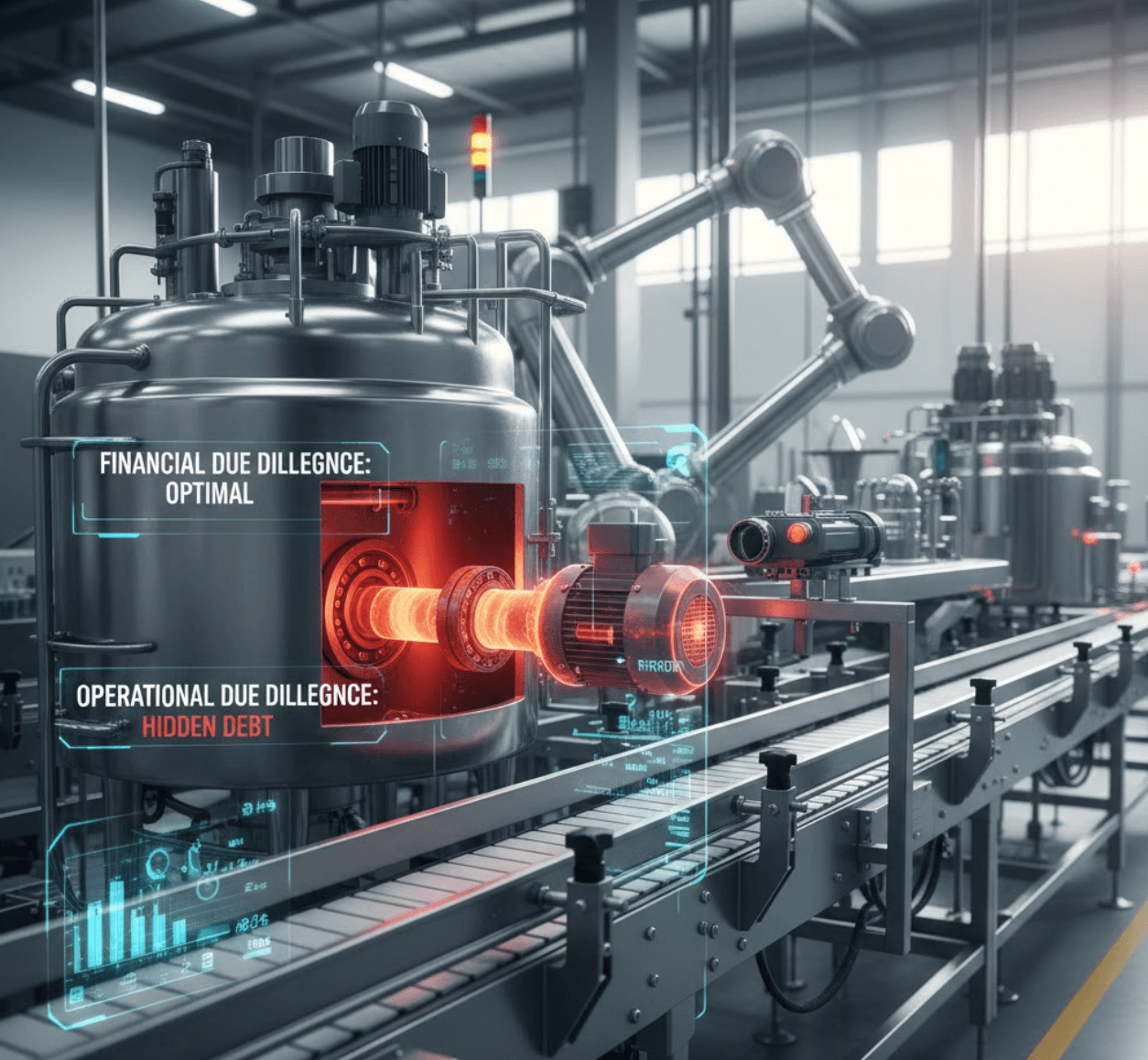

How to Calculate True ROI on Food Processing Equipment: Maintenance Cost vs Value Creation

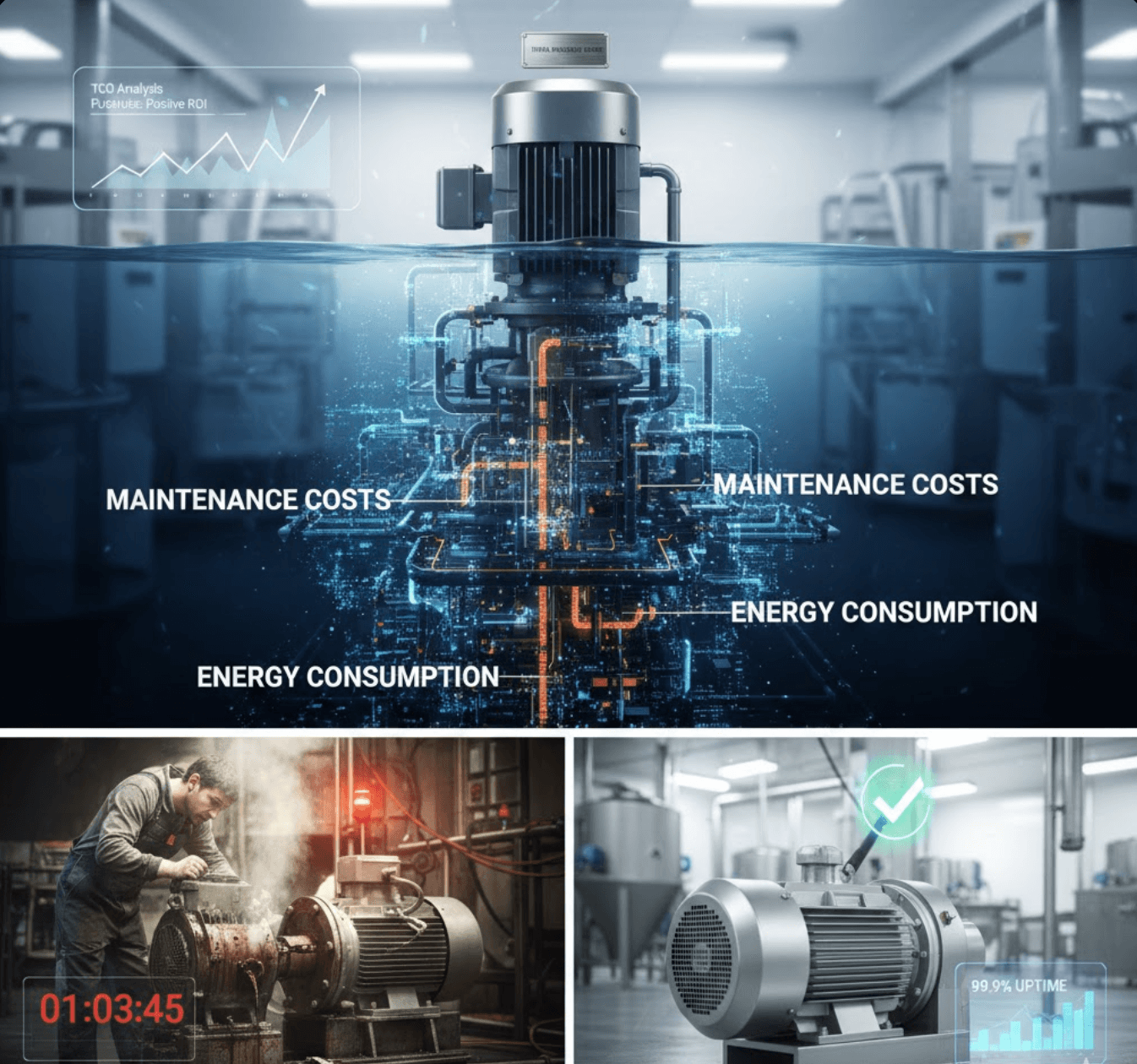

The purchase price represents less than 10% of total cost spent on equipment over its lifetime. Here's how to calculate true ROI using Total Cost of Ownership.