Most food manufacturing capital budgets start with equipment costs. A new separator costs $250K. Site prep adds $30K. Installation costs $45K. Total project: $325K. Budget approved.

Then commissioning begins. The facility needs electrical upgrades ($40K). Floor drains can't handle new discharge rates ($25K). Controls integration takes twice as long as quoted ($15K overrun). Actual project cost: $405K—24% over budget.

This pattern repeats across food manufacturing capital projects because budgets focus on visible equipment costs while missing the complete Total Installed Cost (TIC) picture.

The FEL-1 Budget Framework

Front-End Loading (FEL) is the planning process that creates accurate capital estimates before execution. FEL-1 establishes preliminary cost assessment with ±50% accuracy—enough for corporate budget allocation.

The FEL-1 multiplier for food manufacturing projects typically ranges from 1.25x to 1.5x the equipment purchase price. A $250K separator becomes a $312K-$375K total project when accounting for all components.

Here's the complete line-item framework:

Equipment Costs (Base):

- Primary equipment purchase price

- Ancillary equipment (pumps, valves, controls)

- Spare parts inventory

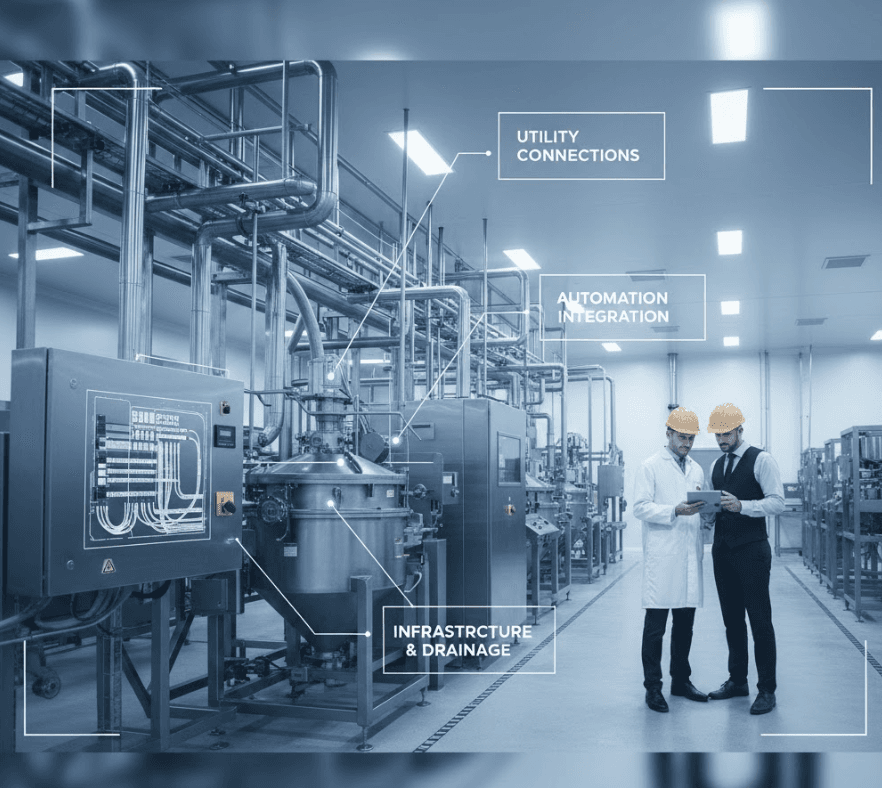

Site Preparation:

- Floor preparation or reinforcement

- Utility connection points (water, power, compressed air, steam)

- Drainage infrastructure upgrades

- Wall or ceiling modifications for equipment clearance

Installation Labor:

- Rigging and positioning

- Electrical hookup

- Plumbing connections

- Process integration with existing lines

Controls & Automation:

- PLC programming

- HMI configuration

- SCADA integration

- Data logging setup

Commissioning & Validation:

- Factory Acceptance Testing (FAT) costs

- Site Acceptance Testing (SAT)

- Process qualification runs

- Documentation and training

Project Management:

- Owner's representation

- Engineering design hours

- Permitting and regulatory compliance

- Third-party inspection costs

The Risk-Adjusted Contingency Approach

Rather than applying a blanket 10-15% contingency to the total, assign risk by category. Mechanical equipment: 5% contingency (well-defined). Electrical and refrigeration: 20% contingency (site-specific variables). Controls integration: 25% contingency (highest unknowns).

This categorical approach provides transparency and can make the difference of millions of dollars on large projects. It allows project teams to focus budget protection efforts on high-risk areas.

Historical Location Costs Matter

Capital costs vary dramatically by region. Labor rates in rural North Carolina differ from metropolitan Chicago. Transportation costs to remote facilities add 10-15% for heavy equipment. Utility connection costs depend on municipal infrastructure proximity.

Accurate FEL-1 estimates require regional cost data—not national averages. A project in Texas using national cost benchmarks will miss regional labor and material pricing differences.

The Business Case Integration

CFOs and PE financial teams should use this framework when evaluating capital requests. A plant manager proposing a $250K separator project should present a complete FEL-1 estimate showing $312K-$375K total installed cost with risk-categorized contingencies.

This level of detail demonstrates operational maturity and provides realistic budget expectations. It prevents the surprise cost overruns that erode post-close EBITDA targets.

For companies planning capital investments, using structured FEL frameworks ensures budget accuracy and enables confident project approval decisions.