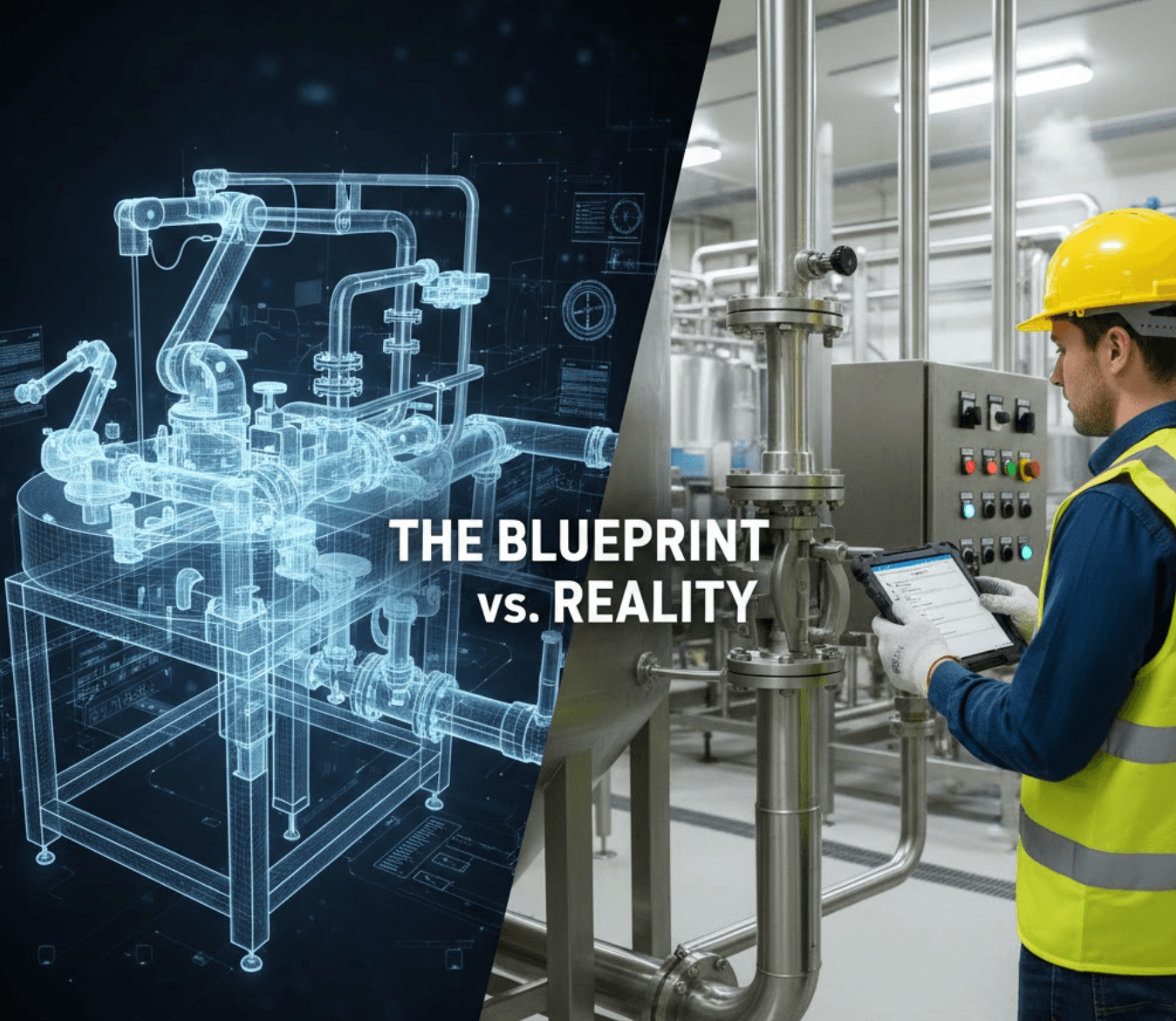

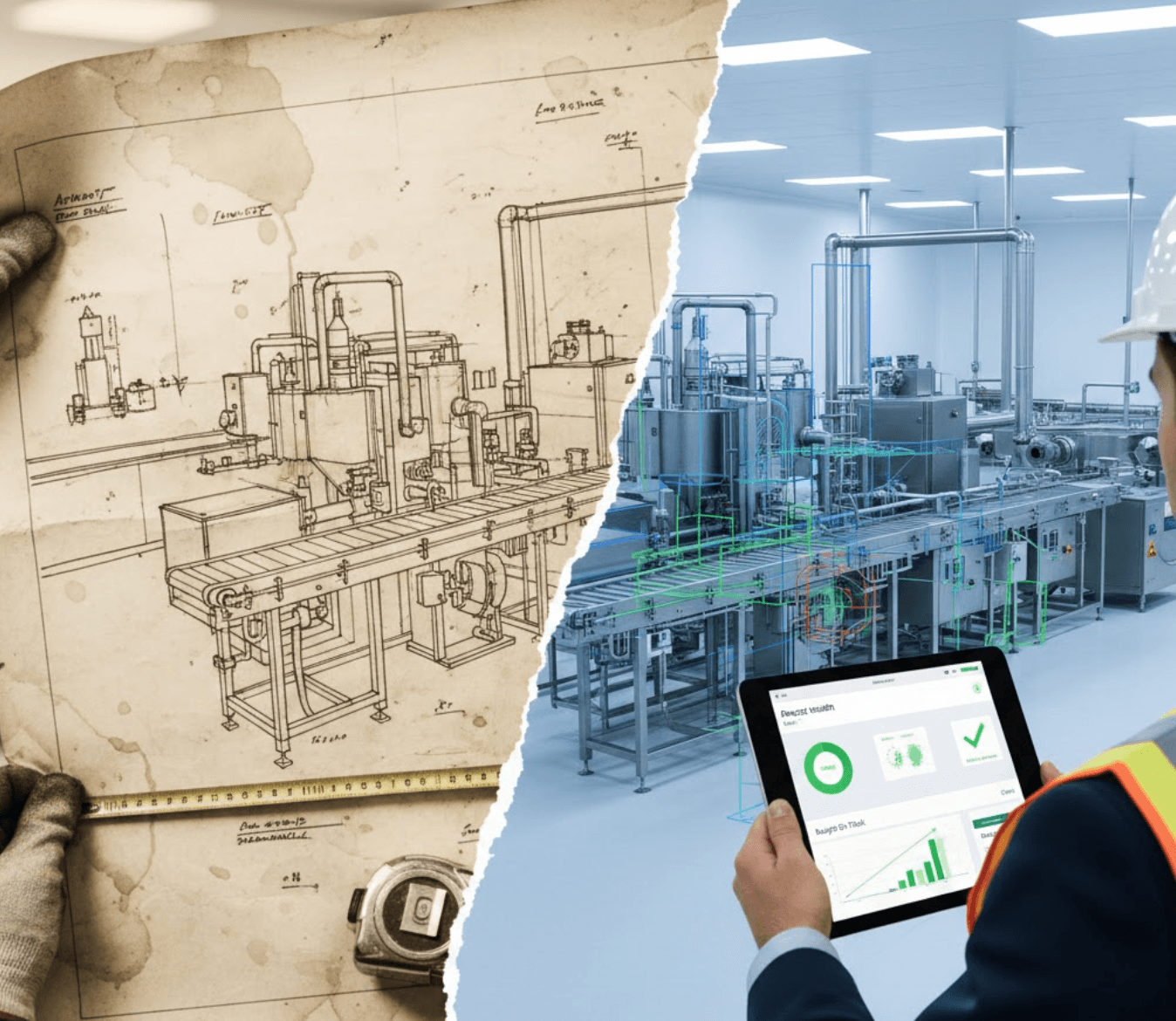

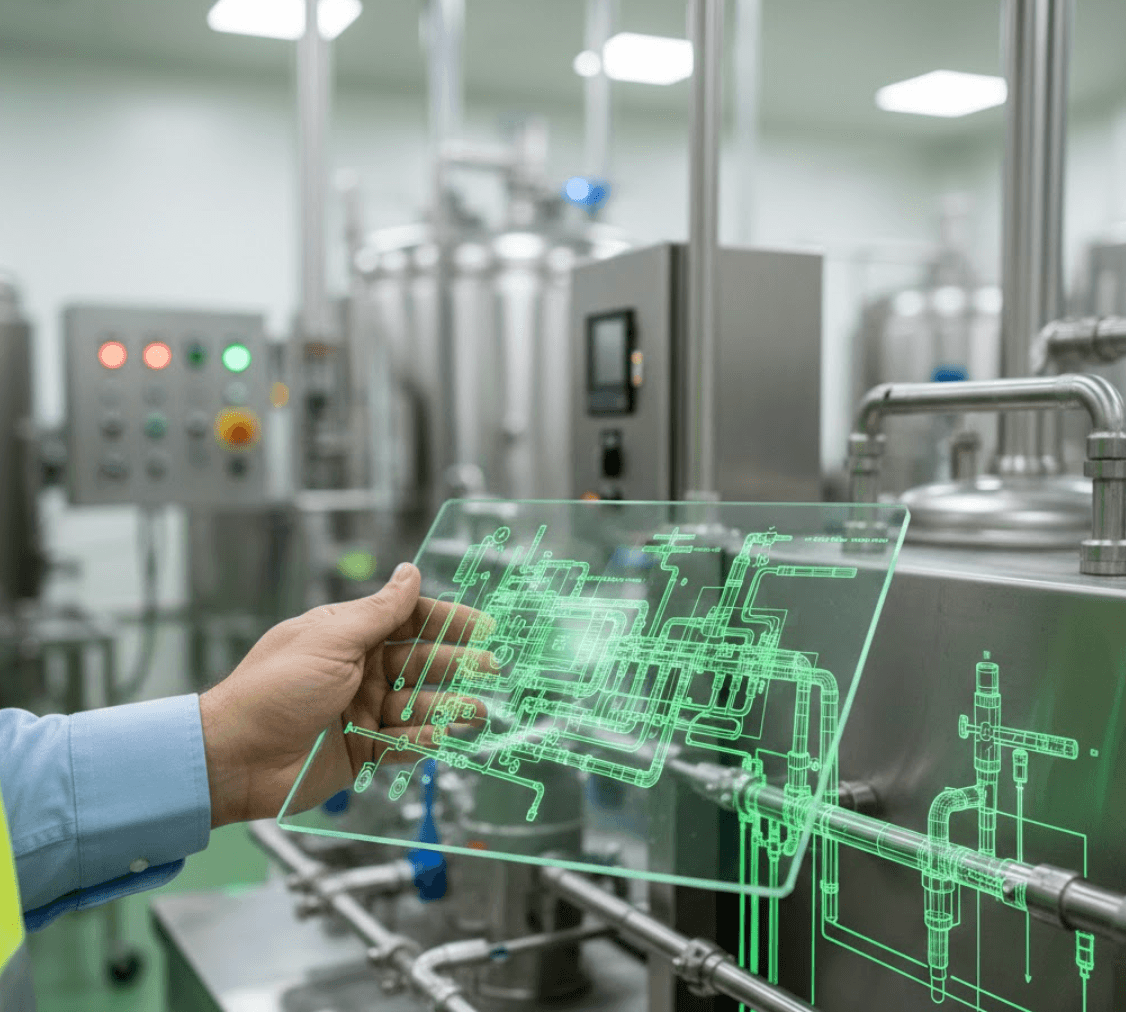

How Accurate As-Builts Reduce Buyer Contingencies and Speed M&A Transactions

M&A transactions in food manufacturing move fast. One variable controls transaction speed more than any other: documentation clarity. As-built drawings and facility specifications are the foundation of operational due diligence.