The Silent Capacity Drain

Your production line is probably running at 60% of its true capacity. You just don't know it.

While you're looking at stated capacity on paper, 20-40% of your actual production capability is vanishing into a silent void—what manufacturing experts call the "hidden factory." This isn't theoretical. It's measured, quantifiable, and fixable.

What's Eating Your Capacity?

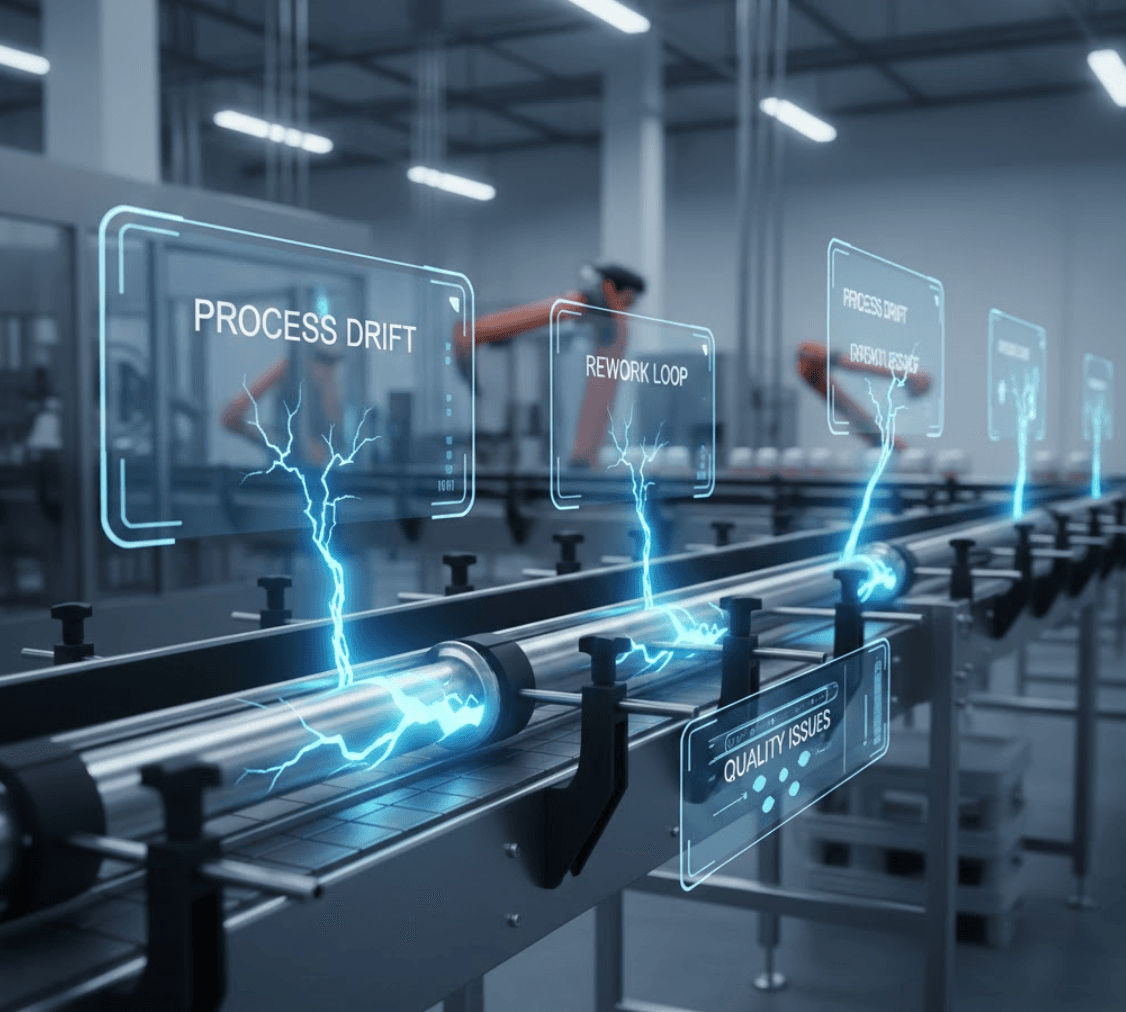

Drifting processes. Out-of-control equipment. Rework loops. Inspection rejects. Variance in ingredient handling. Each is a small leak; together they're a broken pipeline.

A dairy manufacturer's separator states 10,000 gallons per hour capacity. When temperature drifts, when the controller underperforms, when operators compensate for inconsistency—real throughput drops to 6,000 gallons per hour. The missing 4,000 aren't on any report.

A beverage plant claims 50 SKUs per shift changeover. Reality: 3 hours of troubleshooting after every changeover because CIP isn't hitting setpoint consistently. That's 15% of shift-time embedded in the baseline.

The Economics of Hidden Losses

The cost structure compounds:

- Excess material drawn to compensate for process drift (40% more per batch)

- Labor hours spent investigating out-of-spec batches

- Downtime waiting for equipment to stabilize

- Rework of off-spec product (materials + labor + equipment time)

- Slower cycles from conservative operator adjustments

One food manufacturer discovered their rework rate was 8% of production. That's 8 cents of every revenue dollar going to fixing preventable mistakes.

Why This Matters for Investment and Growth

PE firms evaluating acquisition targets assess true capacity versus stated capacity immediately. A plant claiming 100K units/day that consistently runs 65K has a 35% valuation gap nobody's accounting for.

The recovery opportunity doesn't require CapEx expansion. Better process control, tighter equipment maintenance, and consistent operator training unlock hidden capacity already embedded in your equipment.

Finding Your Hidden Factory

Start with your highest-complexity products. Measure:

- Actual cycle time versus theoretical

- First-pass yield (percentage passing inspection on first run)

- Downtime per shift (planned versus unplanned)

- Rework as percentage of production

The gaps represent your hidden factory.

The Operational Audit Approach

Manufacturing operations that identify hidden capacity systematically have data. They track process variability, equipment performance, and actual throughput against baseline assumptions. This requires operational visibility that many plants lack.

Capacity assessments during due diligence and capital planning phases quantify capacity losses and identify bottlenecks. Often, significant capacity recovery happens without major equipment investment—through better process control and reliability.

For companies planning expansion or preparing for strategic transaction, understanding true capacity is foundational to both operational strategy and valuation.