Equipment Selection Framework: How to Avoid Specifying Wrong Technology

Equipment selection success comes from evaluating technology fit with operational requirements—not from vendor features or lowest cost.

Explore our latest insights and updates in Capital Planning.

Equipment selection success comes from evaluating technology fit with operational requirements—not from vendor features or lowest cost.

Lines generating positive contribution margin often justify continued operation despite appearing unprofitable on standard P&Ls. Here's how to decide.

Most facilities have more capital ideas than budget. Here's the multi-criteria scoring framework that ensures capital allocation advances strategic objectives.

The problem isn't usually the business case—it's the presentation. Here's the four-section structure that gets capital requests approved.

Food manufacturing construction projects commonly experience 15-30% cost overruns. Design-build with fixed-price contracts prevents them.

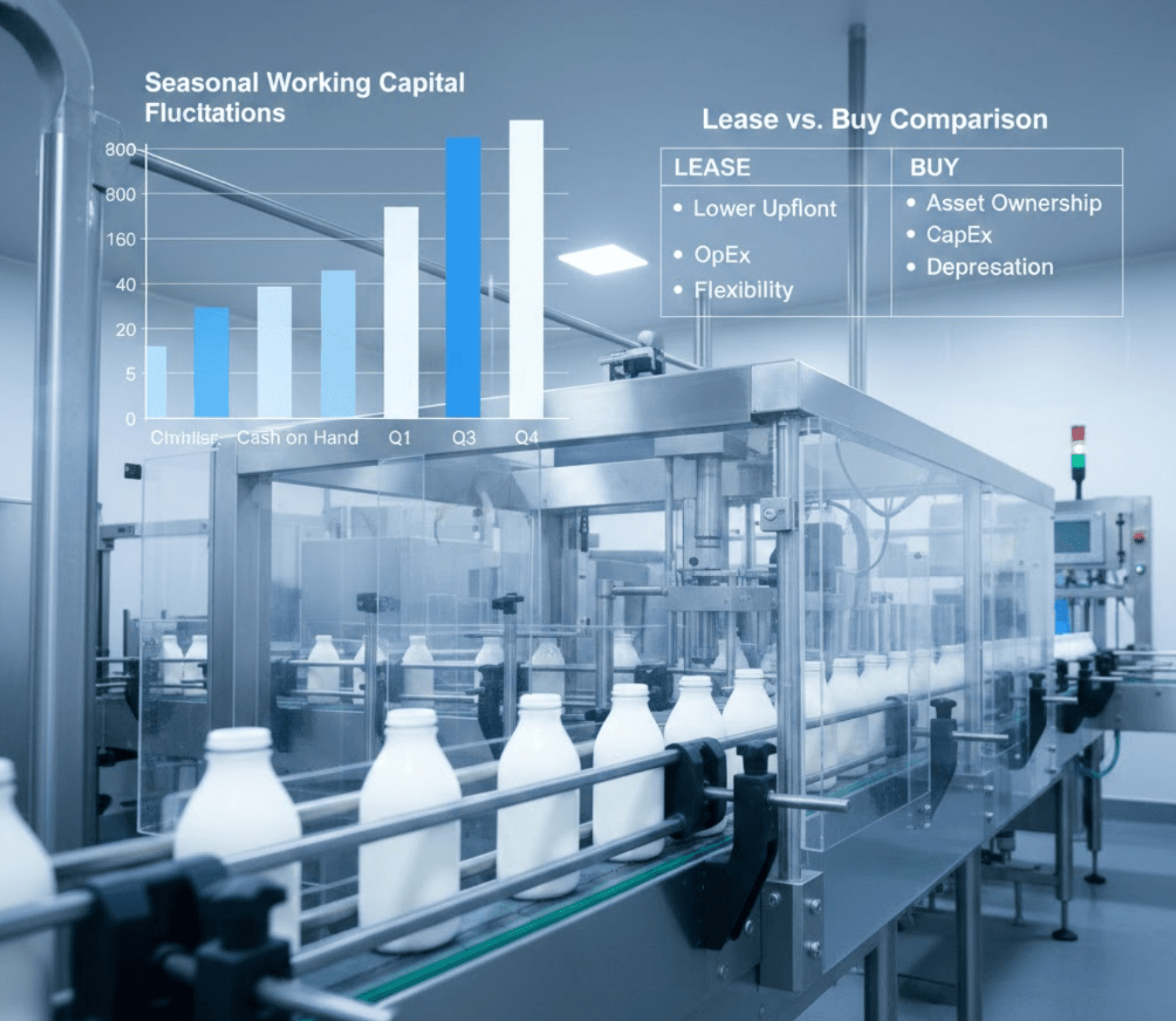

Should you finance equipment or purchase with cash? The answer depends on working capital seasonality, tax position, and balance sheet constraints.

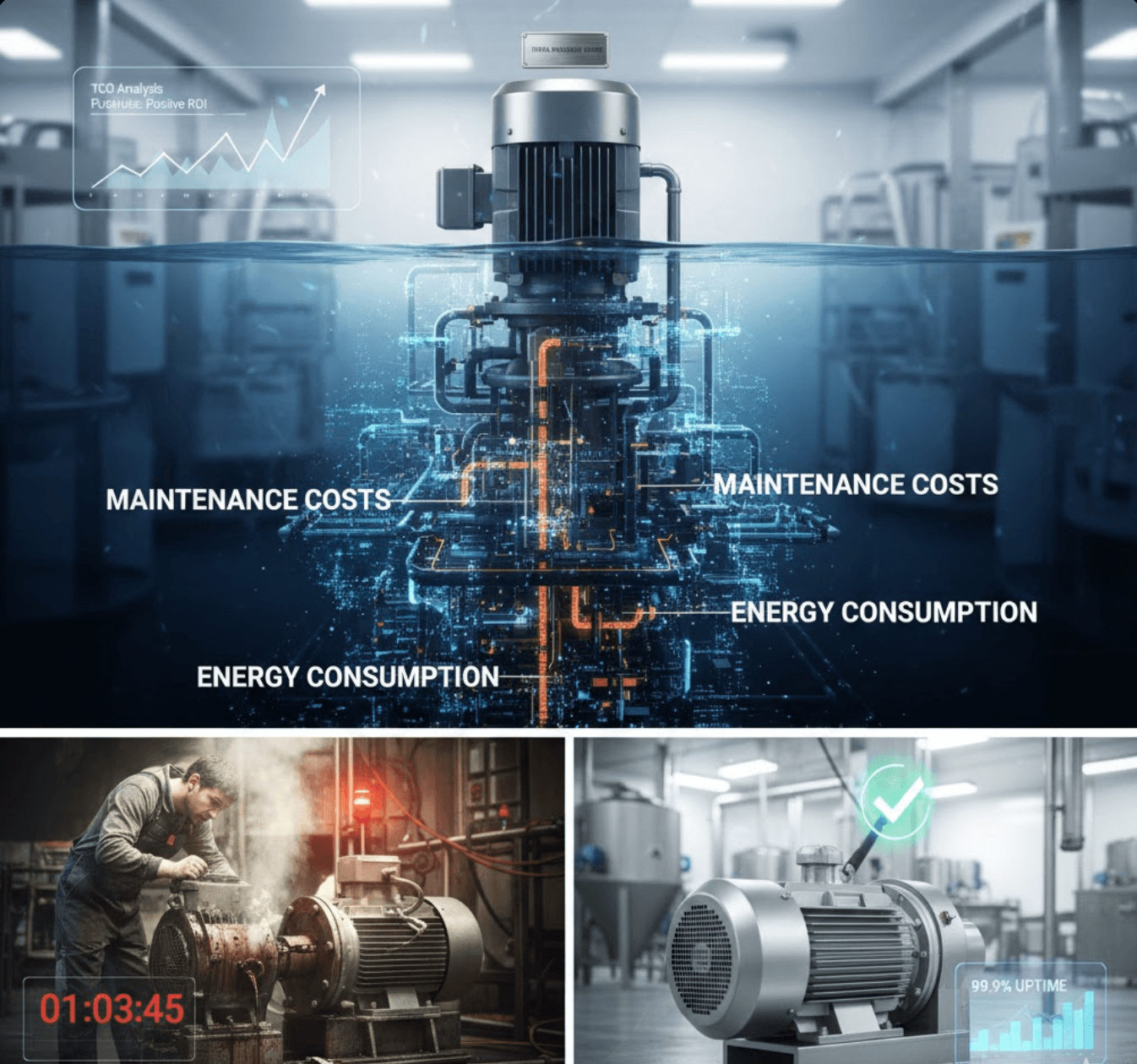

The purchase price represents less than 10% of total cost spent on equipment over its lifetime. Here's how to calculate true ROI using Total Cost of Ownership.

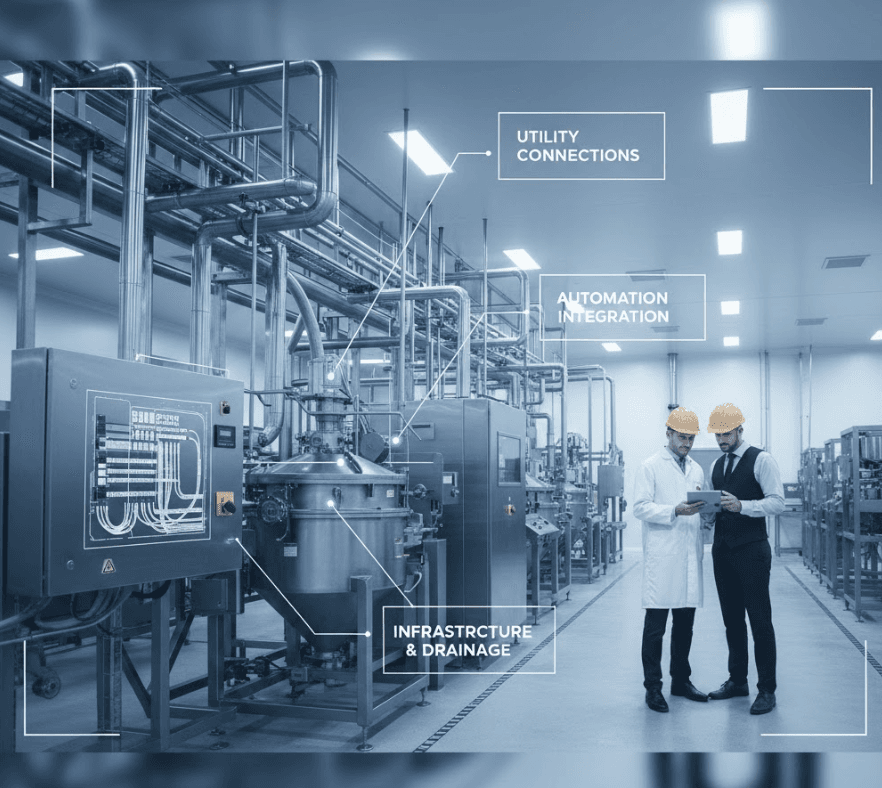

Most capital budgets focus on equipment costs while missing the complete Total Installed Cost picture. Here's the FEL-1 framework that prevents 24% budget overruns.

Most food manufacturers think R&D credits only apply to revolutionary innovations. The reality: routine product development and process optimization often qualify.

MSAs deliver 48%+ first-year ROI through predictable costs, priority scheduling, and economies of scale. Here's the calculator to prove it.